Geberit Mapress Press-Fit Valves Range

Hattersley has designed a dedicated core range of Press-Fit valves, which are quickly and easily installed into pipework using proven Geberit Mapress technology.

Without compromising on reliability, a clean pressed joint is simpler and quicker to make than traditional soldered or threaded connections.

View Hattersley Press-Fit Valves

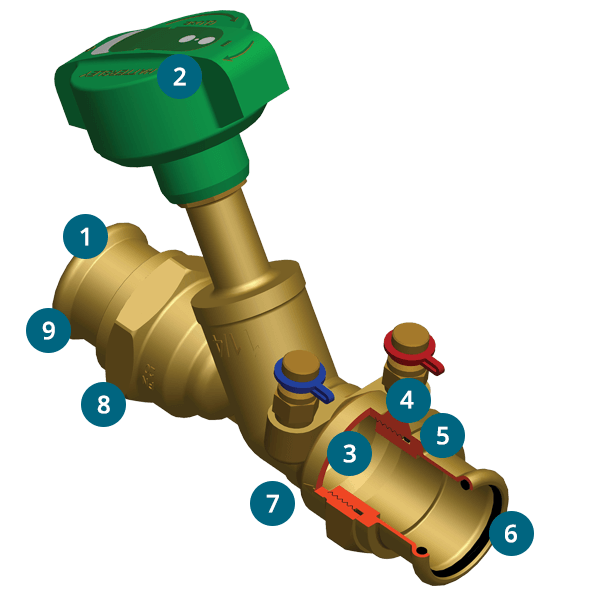

Press-Fit Valve Components

Unique End Cap

A unique end cap has a size indicator and ensures the product is protected from any ingress prior to installation.

PN16 Rated

Valves are PN16 rated and suitable for temperatures -10 to 120°C. Valve is assembled with press-fit ends.

Full Bore End Connectors

End connectors are full bore, maintaining valve performance.

Parallel Threads

Valves & fittings have the advantage of redesigned parallel threads to enhance thread engagement and to ensure the valves pass DVGW vibration and EN 331 bend tests.

O-Ring

Additional O-Ring creates leak-tight seal.

Fail Safe

O-Ring features defined leak paths – a ‘fail safe’ against unpressed joints.

Performance

Exact dimensions, tolerances and performance of entire unit is known in advance.

Preassembled & Tested

Valves are supplied preassembled & factory tested so the number of joints to make on-site is reduced.

Visual Indicator

White foil indicators which surround the pressing contours provide a visual indicator of a pressed joint.

Maximum Performance Benefits

An Outstanding Pedigree

Hattersley and Geberit have been trading for nearly 100 years and bring together their expertise in creating innovative, quality products and solutions th at have been used by specifiers, consultants and contractors around the world.

Designed for the Perfect Fit

Whilst the valves still incorporate the same features & benefits as the trusted Hattersley project valve range, both the fittings and valves have redesigned parallel connecting threads to ISO 228-1.

Pre-assembled & Fewer Joints

Valves come already fitted with Geberit Mapress connectors – so there is just one integral unit. For the fitter, the benefits are huge; the number of joints to make on-site is dramatically reduced and the performance, exact dimensions & tolerances of the Press-Fit Valve are known in advance. This is ideal for pre-fabricators who can pre-cut pipework with confidence.

Thoroughly Tested

Each Press-Fit valve undergoes the standard 6 bar air underwater test. Hattersley also used bend and vibration tests to EN331 and DVGW respectively during development to test the integrity of the fitting.

Geberit Mapress Technology – Peace of Mind

All Press-Fit Valves come with a unique white end cap, which has a size indicator, and ensures that the product is protected from any ingress of material prior to installation. In addition, innovative ‘white foil’ indicators which surround the pressing contours of the connectors are designed to fall off after pressing with a Press-Fit Tool. This enables unpressed joints to be clearly visible before the pressure test. As a further safety enhancement, Press-Fit valves feature defined leak paths, which if unpressed, will cause controlled leakage and be immediately identified during initial testing.

Application – Adapting to Variety

Designed for both new-build and refurbishment projects, Press-Fit valves can be installed on a variety of pipe materials. In addition to any brand of copper tubing conforming to BS EN 1057 R220 soft copper (12-22mm), R250 semi-hard coppper (12-28mm) and R290 hard copper (12-54mm), the valves can also be pressed onto Geberit Mapress Stainless and Carbon Steel.

The Core Range

Hattersley Press-Fit Valves are available in sizes up to 2″ for Ball Valves, Balancing Valves, Check Valves and Strainers.

View Hattersley Press-Fit Valves